Automation in the Manufacturing Industry: Unbundling Human Labor from Production

In the world's most advanced factories, a quiet revolution is underway. For every 10,000 human employees in the manufacturing sector, South Korea now operates over 1,000 industrial robots—a global benchmark in automation density. This staggering statistic isn't just a testament to efficiency; it's a profound signal of a historic shift. We are witnessing the systematic separation of human labor from the act of production, a process I call The Great Unbundling.

This concept, explored in depth in my book, The Great Unbundling: How Artificial Intelligence is Redefining the Value of a Human Being, argues that AI and automation are dismantling the bundle of capabilities—analytical intelligence, physical dexterity, emotional connection—that have defined human value for millennia. The automation manufacturing industry is perhaps the most visceral and tangible example of this unbundling in action.

For the AI-Curious Professional, this article breaks down the specific technologies transforming the factory floor. For the Philosophical Inquirer, it explores what happens to human purpose when the value of our physical labor is outcompeted. And for the Aspiring AI Ethicist, it provides a grounded analysis of the economic and societal shifts that demand new social contracts.

From Artisan to Assembly Line: A Brief History of Bundled Labor

To understand where we are going, we must first understand what we are leaving behind. The history of manufacturing is a history of bundling and unbundling human skill.

The Integrated Craftsman

For centuries, the artisan was the pinnacle of bundled capability. A blacksmith didn't just possess the physical strength to hammer steel; they held the metallurgical knowledge to select the right ore, the artistic vision to design a tool, and the business acumen to sell it. Their intelligence, dexterity, and economic survival were inextricably linked in a single person. This was the age of the perfectly bundled individual.

Fordism and the First Unbundling

The Industrial Revolution, and specifically Henry Ford's assembly line, initiated the first major unbundling. The complex craft of building a car was deconstructed into simple, repeatable tasks. This manufacturing process automation—though mechanical rather than digital—unbundled specialized knowledge from physical action. A worker no longer needed to be a master craftsman; they only needed to perform a single, repetitive function. Capitalism, as the engine of this change, rewarded this unbundling with unprecedented scale and efficiency.

The Engine of Efficiency: How Automation in the Industry Drives Unbundling

Today's manufacturing automation represents a far more profound unbundling, driven by AI and robotics. It's not just about separating tasks but about unbundling core human attributes from the production process entirely. Where a human worker brought a bundle of strength, dexterity, and sensory judgment (sight, touch), a robot now unbundles and perfects each one individually.

Key Benefits of Automation in Manufacturing

The undeniable advantages of modern automation are the economic drivers of the Great Unbundling:

- Unbundling Precision and Endurance: A human welder can be highly skilled but is subject to fatigue, minor inconsistencies, and physical limits. A robotic welding arm performs the same task 24/7 with micron-level precision, drastically improving quality and throughput.

- Unbundling Strength and Safety: Automation removes humans from dangerous environments. Robots handle heavy lifting, toxic materials, and repetitive motions that lead to injury, unbundling physical labor from human risk. According to the Bureau of Labor Statistics, robotics can help reduce the over 100,000 annual injuries in the manufacturing sector related to overexertion and bodily reaction.

- Unbundling Sight and Judgment: AI-powered computer vision systems can inspect products on an assembly line faster and more accurately than the human eye. They can detect microscopic flaws a person would miss, unbundling the act of "seeing" from the fallibility of human perception.

Current Automated Manufacturing Technology Examples

This unbundling is made possible by a suite of technologies:

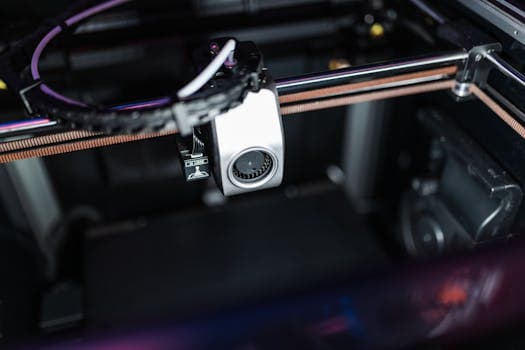

- Industrial Robots (Articulated Robots): These are the workhorses seen in automotive plants, performing tasks like welding, painting, and assembly.

- Collaborative Robots (Cobots): Designed to work alongside humans, cobots handle tedious or non-ergonomic tasks, allowing human partners to focus on higher-value activities that require judgment or fine-motor skills.

- Autonomous Mobile Robots (AMRs): These intelligent vehicles navigate factory floors to transport materials, unbundling the human task of logistical coordination and movement.

- AI-Powered Quality Control: Vision systems integrated with machine learning algorithms identify product defects, continuously learning and improving their accuracy. A 2022 McKinsey report notes that AI-driven quality control can reduce inspection costs by up to 35%.

Beyond the Factory Floor: The Unbundled Worker and the Future of Value

The automation manufacturing industry serves as a crucial case study for the central thesis of The Great Unbundling. When you unbundle capabilities and perfect them in machines, you fundamentally change the economic value of the original human bundle.

The Economic Realities: Job Displacement and Skill Shifts

The data is sobering. A landmark Goldman Sachs report suggests that as many as 300 million full-time jobs worldwide could be exposed to automation by AI. While manufacturing has seen this trend for decades, generative AI is accelerating it into cognitive and administrative roles within the industry.

The discussion is no longer just about blue-collar jobs. It's about engineers whose design work can be augmented by AI, supply chain managers whose logistical planning is optimized by algorithms, and floor managers whose oversight is replaced by sensor networks. This isn't a simple replacement of one worker with one robot; it's the unbundling of functions from entire job categories.

The Philosophical Question: When Does a Worker Stop Being Human?

As we unbundle more capabilities, we must confront a difficult question. The humanist tradition places immense value on the integrated individual—the person who thinks, feels, and acts in the world. What is the value of a human in a system that only requires their physical presence to oversee a machine, their finger to press a button, or their brain to handle the one exception the algorithm can't solve? We risk creating a world where human participation is reduced to filling the ever-shrinking gaps left by machines.

The Great Re-bundling: Finding New Purpose in an Automated World

The Great Unbundling is not a dystopian inevitability but a challenge that demands a conscious human response. This response is The Great Re-bundling: a deliberate effort to re-integrate our capabilities in new ways that create value beyond what machines can offer.

Cobots and Human-Machine Collaboration

The most optimistic application of automation in industries involves collaboration, not replacement. A "cobot" scenario allows a human to re-bundle their cognitive skills with a robot's strength and precision. The human handles complex problem-solving, adaptation, and customization, while the machine handles the brute force, creating a hybrid capability greater than either could achieve alone.

The Rise of the "Artisan Technologist"

Just as the first Industrial Revolution gave way to a new class of engineers and mechanics, the AI revolution will create new roles. The "Artisan Technologist" is a worker who re-bundles deep domain knowledge (e.g., in advanced materials) with technical skills (operating complex robotic systems) and creative problem-solving. This is not the mass-production worker of the 20th century but a highly skilled individual creating bespoke value.

Policy for a Post-Automation Era: Is UBI the Answer?

If the automation manufacturing industry demonstrates that full employment in the traditional sense may become structurally impossible, we must consider new social contracts. Universal Basic Income (UBI) is not a political policy choice but may become a civilizational necessity. It provides a floor of economic security, allowing individuals the freedom to pursue the education, creative work, and community-building that will form the basis of our re-bundled future. This is a topic that requires serious, non-partisan exploration.

The Future of Manufacturing Process Automation

Looking ahead, the trend is toward "hyper-personalization," where factories can produce custom goods on demand with the efficiency of mass production. This is only possible through end-to-end automation, where AI manages the entire process from order intake to final shipment. This represents the near-total unbundling of the manufacturing process from direct human intervention.

Conclusion: Navigating the Unbundled Factory

The automation manufacturing industry is more than just a sector of the economy; it is a live laboratory for the future of human work and value. The relentless drive for efficiency, fueled by capitalism and technology, is successfully unbundling human capabilities at a pace we are only beginning to comprehend.

Understanding this dynamic through the framework of The Great Unbundling allows us to see past the headlines about job losses. It equips us to ask more profound questions: How do we foster a "Great Re-bundling"? What new skills will be valuable? And what societal structures must we build to ensure that the immense wealth created by automation serves human ends?

The factory of the future is being built today. It's our choice whether we become mere ghosts in the machine or the architects of a new, more purposeful human role within it.

To delve deeper into the forces shaping our automated future and explore the path toward a human-centric response, read The Great Unbundling. Purchase your copy here or sign up for our newsletter to receive ongoing analysis.